Path to Become a Paradigm Changer from Within

Aiming for High-performance Next-generation Photovoltaic Modules

– Fusion of Thin-film Photovoltaic Module Technology into Heterojunction Technology

Aiming to achieve carbon neutrality by 2050, as declared by the Japanese government in October 2020, we support a clean society with high-performance next-generation photovoltaic modules, centering on technological fusion through enhanced industry-academia-government collaboration.

Social Implementation of a Wall-Installable Photovoltaic System

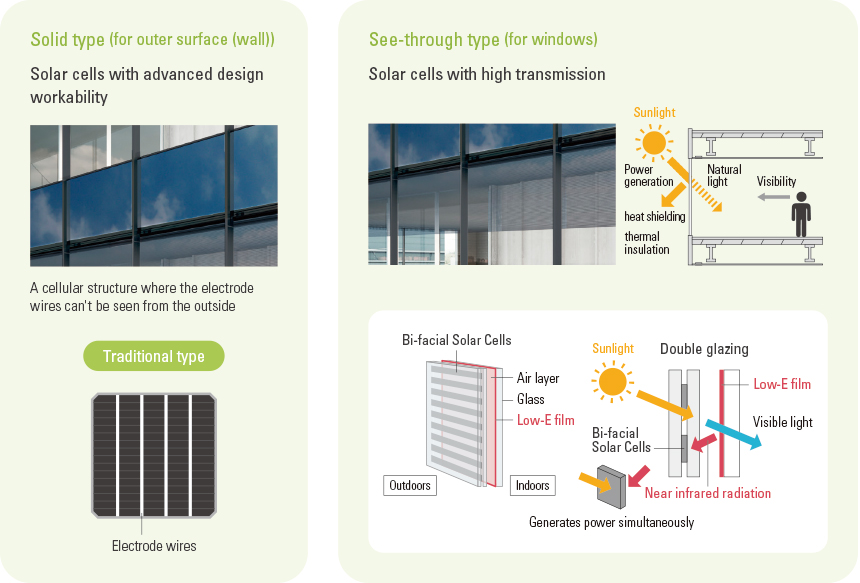

In December 2019, we developed the exterior system “T-Green® Multi Solar,” which generates electricity through photovoltaic laminates integrated into outer walls and windows, through the joint development of a wall-installable photovoltaic system with Taisei Corporation. (“T-Green” is a registered trademark of Taisei Corporation.) A next-generation see-through photovoltaic module integrated into windows was developed as a new building integrated photovoltaic (BIPV) with increased power generation and thermal insulation by low-E multi-layered glass(*1) through combination of our bi-facial heterojunction photovoltaic cell technology and low-E glass. With a cellular structure with electrode wires invisible from the outside, a solid-type photovoltaic module for outer walls features advanced design workability as a high-efficiency photovoltaic module adaptable to spandrel areas(*2) of building exterior. With two types of modules combined, the system can be applied to various outer walls including glass curtain walls(*3). High-efficiency crystalline Si see-through photovoltaic modules have been used for the roof eaves of the Japan National Stadium. Both companies have begun developing photovoltaic modules integrated with precast concrete(*4) and renewed PVs for existing buildings toward the expanded use of BIPVs.

We aim to realize a power-generating house/building equipped with high-performance next-generation photovoltaic modules toward the realization of a carbon neutral society.

*1 Low-E multi-layered glass: Multi-layered glass that uses glass coated with a special metal film (Low-E glass).

*2 Spandrel area: The area of outer walls specified in Article 112 of the Order for Enforcement of the Building Standards Act. To prevent the passage of fire from one opening to another, a space or a waist-high wall is placed between each opening.

*3 Glass curtain wall: A wall that does not support the structural load of a building, such as all-glass walls and panel outer walls.

*4 Precast concrete: A concrete product manufactured at a plant and transported to the construction site, or a construction method using precast concrete members.

Sample of utilization

Interior of the Japan National Stadium (Courtesy of Taisei Corporation)

The Merits of the SolidType (for Outer Surfaces (Wall)) and the See-through Type (for Windows)

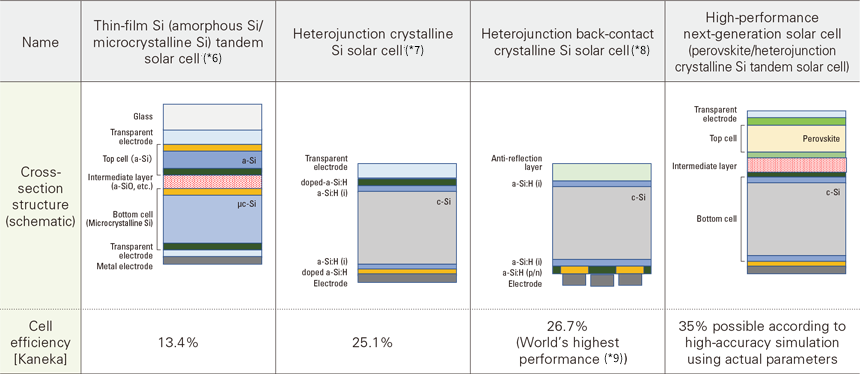

From Thin-film Si Tandem Solar Cells to Heterojunction Crystalline Si Solar Cells

Crystalline Si photovoltaic modules account for 95% of the world's photovoltaic module production.

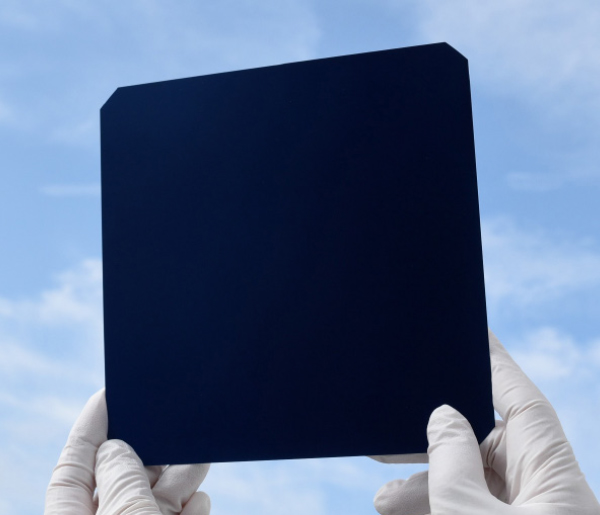

We have achieved the world’s highest cell conversion efficiency of 26.7% and module conversion efficiency of 24.5% in heterojunction back-contact crystalline Si solar cells (Photo 1), using our heterojunction technology developed based on thin-film Si tandem technology.

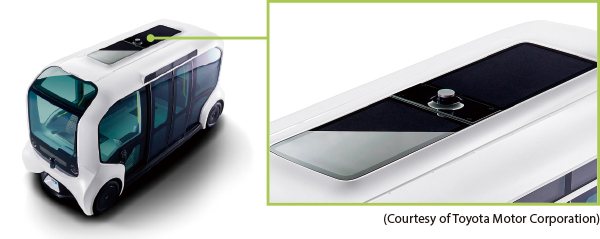

We are advancing R&D to implement this technology in application as in-vehicle solar cells (Photo 2). For its development, it is crucial to lower the cost and increase the efficiency of solar cells as well as to reconcile our technology with the customer’s technology. We are working to adapt this technology to a new style of society, including a mobility application.

(Photo 1) Heterojunction back-contact crystalline Si solar cell

(Photo 2) Kaneka’s solar cell installed in the roof glass of Toyota’s low speed automatic driving EV “e-Palette”

Development from Heterojunction Crystalline Si Solar Cells to High-performance Tandem Solar Cells

We are engaged in R&D of a high-performance next-generation solar cell (perovskite/heterojunction crystalline Si tandem solar cell) composed of our heterojunction crystalline Si solar cell as a bottom cell and a perovskite solar cell(*5) as a top cell.

In this combination, the intermediate layer, developed for thin-film Si tandem solar cells, plays a key role. High-accuracy simulation using actual parameters concluded that a conversion efficiency of 35% could be achieved. In our verification, we have achieved the world’s highest conversion efficiency level of nearly 30% for a small area (1 cm²). In its practical use, our technologies, developed for thin-film Si tandem solar cells, will contribute to differentiation of the product.

High-efficiency solar cells are effective in reducing levelized cost of electricity (LCOE) and allow for expansion into new markets. An increase in conversion efficiency leads to an equivalent increase in power generation in the same area, leading to the reduction of environmental load.

Type, Structure and Conversion Efficiency of Our Solar Cells

*5 Perovskite solar cell: A solar cell composed of the perovskite-structured compound as a light absorption layer.

*6 Thin-film Si tandem solar cell: A stacked solar cell composed of amorphous and microcrystalline Si thin film layers as light absorbing layers. A tandem solar cell comprises top and bottom cells that absorb short-and long-wavelength light, respectively. A stacked cell structure can increase conversion efficiency.

*7 Heterojunction crystalline Si solar cell: A crystalline Si solar cell with a heterojunction formed by crystalline and amorphous Si. Heterojunction technology binds semiconductor materials with different physical properties and can improve conversion efficiency through defect reduction.

*8 Heterojunction back-contact crystalline Si solar cell: A crystalline Si solar cell that combines heterojunction and back-contact technologies. Back-contact technology, with electrodes formed only on the back face of the solar cell, can make the light receiving area of the top face larger, resulting in better conversion efficiency.

*9 Solar cell efficiency tables (Version 57), Prog. Photovolt. Res. Appl. 2020;1–13