A Limitless Adventure

Manufacturing Strategies

Achieving a sustainable plant

that combines digital transformation with carbon neutrality

Carbon Neutrality

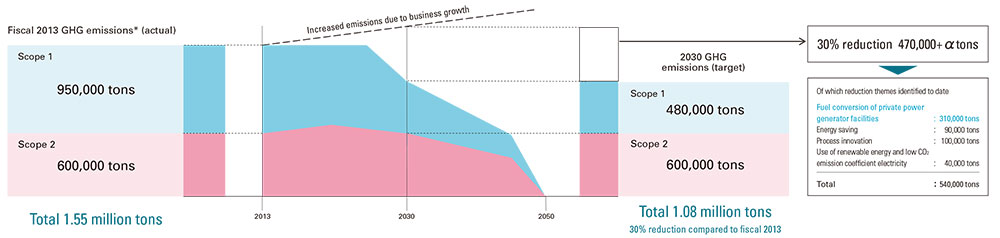

The Kaneka Group aims to reduce Scope 1 and 2 GHG emissions, which include domestic and overseas Group companies, by 30% by 2030 (compared to fiscal 2013) and to achieve carbon neutrality by 2050.

We are currently working to identify and implement themes for reducing GHG emissions.

To further accelerate capital investment,we have designed an internal carbon pricing system, which will be operational from fiscal 2023.

Achieving 2030 Targets Toward Carbon Neutrality

In 2030, we will achieve our goal by lowering energy consumption through fuel conversion of private power generator facilities and process innovation, reducing mainly Scope 1 GHG emissions.

Scope 2 will change with the spread of renewable energy and other factors, but at this stage we are estimating limited GHG emissions reduction. We will continue to monitor changes in the external environment and act accordingly.

* GHG emissions: a value indicating the sum total of energy-origin CO2 emissions, non-energy-origin CO2 emissions, and the CO2 equivalents of methane and N2O emissions, calculated in accordance with the GHG protocol.

Progress to Date - Identifying GHG Emissions Reduction Themes -

In fiscal 2022, for the GHG emissions reduction of 30% (470,000+αtons) set out in our 2030 target, we have identified themes for 540,000 tons. We will proceed with technical verification for each theme. Going forward, we will expand our GHG emissions reduction themes to domestic and overseas Group companies.

We will actively incorporate Scope 2 reduction measures, including at our overseas sites.

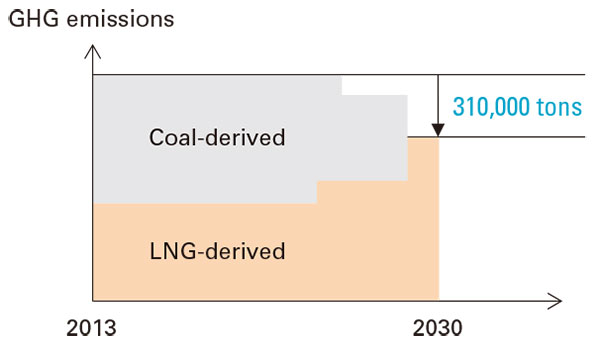

1) Fuel Conversion

The fuel for private power generators at Takasago Manufacturing Site will be converted from coal to natural gas (LNG) in stages, and the use of coal will be discontinued by 2030.

2) Energy Saving

As a new energy saving technology, we have started to examine exhaust heat recovery by heat pumps, which has a wide range of application for each of our plants.

3) Process Innovation

We are acquiring pilot demonstration facilities to establish innovative technologies at our manufacturing plants, including vinyl chloride monomers.

4) Use of Renewable Energy and Low CO2 Emission Factor for Electricity

Kaneka (Malaysia) Sdn. Bhd. has started to purchase low CO2 emission factor for electricity as a way of reducing Scope 2 emissions. In addition, we are promoting the use of renewable energy, through measures such as installing in-house photovoltaic modules and self-transporting the power that we generate.