Kaneka releases the new Temperature Controlled Package TACPack™ Premium

—Vastly increases the time that temperature control can be maintained by adopting vacuum insulation panels—

April 14, 2020

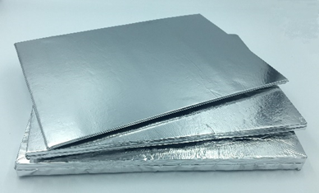

Tamai Kasei Co., Ltd. (Headquarters: Otaru, Hokkaido; President: Keiji Sato), an affiliate of Kaneka Corporation (Headquarters: Minato-ku, Tokyo; President: Minoru Tanaka), will from April begin selling their new product, the "Temperature Controlled Package TACPackTM Premium Series" (referred to below as "TACPackTM Premium") that uses vacuum insulation panels*1 (referred to below as "VIP") to extend the time that temperature control can be maintained by around twice as much.

In 2018, the Japan edition of the GDP*2 guidelines were established, requiring stricter thermal management during the transportation of medicines. Products with insulated containers made of polystyrene foam had limits imposed on the time that cold storage temperature must be maintained during the summer period, creating a problem for transportation that took long hours. By combining silica powder core system VIP*3 and Kaneka phase change material PATTHERMO TM *4, TAC Pack TM Premium is able to maintain the temperature within packaging for longer hours and, compared with conventional products, can increase the time that temperature control can be maintained by around two-fold.

Currently, with a new latent heat storage material also being developed, Kaneka will continue to expand upon the TACPackTM Premium lineup to accelerate the development of the market. In the long term as well, Kaneka will contribute to raising the quality of medical treatment and of people's lifestyles through providing thermal management solutions.

- Heat insulators using a vacuum technique that heightens the vacuum ability by turning the area surrounding the heat insulator into a vacuum and bringing the thermal conduction caused by gas exceedingly close to zero.

- Abbreviation of Good Distribution Practices. These guidelines stipulate appropriate control methods for the purposes of ensuring quality and preventing the inflow of fake drugs chiefly in regard to the distribution of medicines. They were issued by Japan's Ministry of Health, Labor and Welfare at the end of December 2018.

- Compared to glass fiber type VIP that are the mainstream in Japan, silica powder core system VIP is lighter and has less degradation of thermal conductivity performance that occurs due to the rise in internal pressure.

- A phase change is when a substance's condition changes between being solid, liquid or gas, and latent heat storage materials during phase changes have an advantage where the temperature of their substance is kept close to melting temperature or solidifying temperature. PATTHERMOTM is a phase change material jointly developed by Kaneka and Tamai Kasei, and its lineup consists of 15 kinds of products within the range of -50℃ to +37℃ .

About the Temperature Controlled Package TACPackTM Premium Series

- Manufacture and sale

- Tamai Kasei Co., Ltd.

- Internal temperatures

- 2 to 8℃, below -40℃ (April release)

Below -60℃, 1 to 5℃, 15 to 25℃ (planned for future market release)

<General description of Tamai Kasei Co., Ltd.>

- Headquarters

- Otaru, Hokkaido

- Description of business

- Casting and processing of styrene foam resin, manufacturing and sale of energy storage materials, manufacturing and sale of Temperature Controlled Package TACPackTM

- President and Representative Director

- Keiji Sato

- Shareholders

- 100% funded by Kaneka Corporation