Manufacturing Strategy

Carbon Neutral (CN)

Creating manufacturing sites that embody sustainability to promote global health

Kaneka Group supports the principles of the TCFD. Through scenario analysis, we identify climate-related risks and opportunities and develop strategies for the medium to long term.

We have also joined the GX League (*1) to advance our carbon neutrality initiatives.

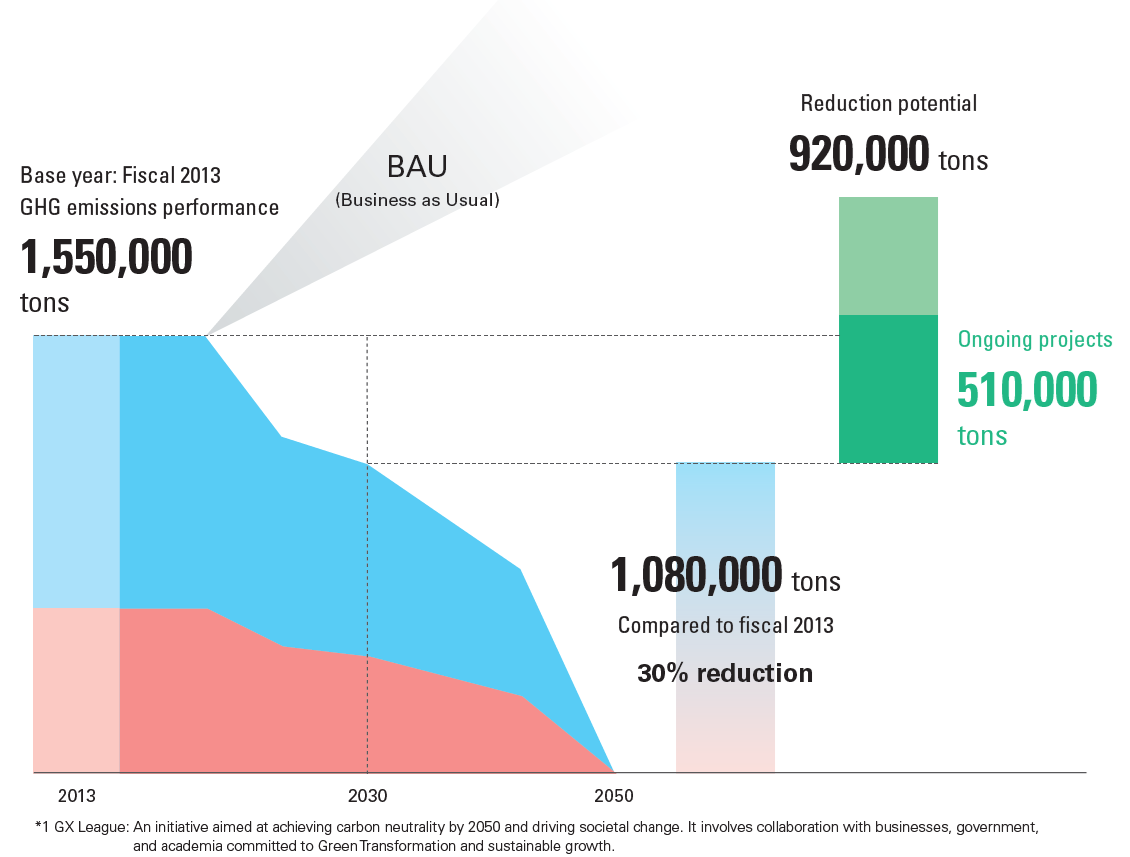

Based on these principles, Kaneka Group aims to cut its Scope 1 and 2 GHG emissions by 30% by 2030, compared to fiscal 2013 levels. We aim to achieve carbon neutrality for domestic and international subsidiaries by 2050.

We will continue to use our established production expertise to reduce GHG emissions. We will implement new development themes and advance ongoing energy saving initiatives at our manufacturing sites.

We will also collaborate across external organizations to contribute to global health.

Approach to Setting GHG Emission Reduction Targets

We aim to cut GHG emissions by 470,000 tons, or 30%, from the fiscal 2013 baseline by 2030. We anticipate reducing emissions by 510,000 tons by fiscal 2024 through fuel conversion at the Takasago Manufacturing Site and other measures.

To balance future business growth with emission reductions, we will identify potential GHG emission cuts through energy saving process innovations. We will develop economically viable plans that consider internal carbon pricing.

| GHG emissions reduction theme total potential | Ongoing projects | Progress | |

|---|---|---|---|

| 1. Fuel conversion | 310,000 tons | 310,000 tons | Decision to divest from coal: 310,000 tons |

| 2. Energy saving | 300,000 tons | 26,000 tons | Operational |

| 3. Process innovation | 100,000 tons | 4,000 tons | Operational |

| 4. Use of renewable energy, low CO2 emission factor for electricity and steam power | 210,000 tons | 170,000 tons | Kaneka Malaysia Decision to introduce biomass boilers, etc. 70,000 tons Power company emission factor reduction 100,000 tons |

| GHG emissions reduction Total | 920,000 tons | 510,000 tons |

Progress to Date

1) Projects that have progressed to a highly feasible phase

Scope 1: We have decided to accelerate our coal phase-out by three years, moving the target from 2030 to 2027. The Takasago Manufacturing Site is progressing as planned with the installation of a new gas turbine cogeneration system. This initiative aims to phase out coal and reduce GHG emissions by 2027.

Scope 2: Kaneka Malaysia has finalized a contract with a supplier to switch to biomass-derived steam by 2026. We expect this to reduce GHG emissions by approximately 30,000 tons. At the Takasago Manufacturing Site, we anticipate reducing GHG emissions by approximately 100,000 tons due to lower emission factors from the power company.

2) Unlocking potential

We are not only investigating GHG emission reduction themes within our domestic and international group companies, but also exploring external partnerships. By sourcing low-GHG energy, we are expanding our potential to reduce GHG emissions.

Disclosure of Information in Line with TCFD Recommendations

In March 2021, Kaneka announced its support for the recommendations of the Task Force on Climate-related Financial Disclosures (TCFD).

Governance

The Global CSV (Quality Environment) Center at the Corporate Manufacturing Integrity Center manages the risks and opportunities related to climate change.

We collaborate with business, production, and research divisions to address climate change risks and formulate prevention strategies. Proposals are reviewed by the Engine of Sustainability Management, led by the Executive Vice President from the Global CSV (Quality Environment) Center. We work closely with all departments to implement solutions.

In particular, the DX & Carbon Neutral Committee, part of the Engine of Sustainability Management, leads our manufacturing strategy for carbon neutrality. This committee collaborates with business units, staff departments, manufacturing sites, research centers, and group companies. Together, they integrate digital transformation with carbon neutrality efforts in manufacturing. The activities of the DX & Carbon Neutral Committee are reported to the Engine of Sustainability Management. Future action plans are then reviewed and decided, and these are incorporated into business plans and other strategies.

Matters of particular importance are reported to the Board of Directors.

Strategy

We have summarized the most significant climate change risks and opportunities for the Company in the table on the right.

In fiscal 2023, we analyzed the expansion of solar power, the increased use of biomass plastics, and the rising demand for effective waste utilization as significant business opportunities. We conducted this analysis under both the 1.5°C and 4°C scenarios and shared the findings with relevant departments. We have integrated the main strategies into our business plan, and will continue to advance these efforts.

Risk Management

The Global CSV (Quality Environment) Center leads scenario analysis on climate change risks and opportunities. We share the strategies with business units and integrate them into our business plans. Production-related measures are proposed and reviewed by the DX & Carbon Neutral Committee and the Production DX & Carbon Neutral Project Committee.

Metrics and Targets

Kaneka Group aims to achieve carbon neutrality by 2050. As a milestone, we have set a target to reduce GHG emissions by 30% by 2030, compared to fiscal 2013. In fiscal 2023, Kaneka Group’s total Scope 1 and Scope 2 GHG emissions amounted to 1,513 thousand tons-CO2e, which is 97.9% of the levels recorded in fiscal 2013.

Kaneka’s standalone Scope 3 emissions amounted to 3,006 thousand tons-CO2e.

Since fiscal 2022, we have been gradually expanding the scope of Scope 3 emissions calculations for our group companies. We plan to consider a strategy for reducing Scope 3 emissions in the future.

Please visit our official website "Climate Change Initiatives" to view our performance up to fiscal 2023.

Major Climate Change Risks and Opportunities: Business Impact and Countermeasures

| Type | Changes in society | The impact of climate-related risks and opportunities on the organization's business, strategy, and financial plans (●Risks/●Opportunities) |

Countermeasures (◎indicates priority areas) |

|---|---|---|---|

| Regulatory/ Legal | Strengthening of GHG emissions regulations | ● Depreciation and amortization costs arising from GHG emissions reduction |

|

| Regulatory/ Legal | Increased operational costs due to introduction of carbon tax (incl. supply chain) | ● Increase in operating costs due to the introduction of carbon tax |

◎ Early fuel conversion of private power generator facilities

|

| Technological | Acceleration of the circular economy |

● Increase in procurement costs due to taxes on the production of petrochemical-derived packaging plastics ● Growing demand for products that contribute to the realization of a circular society, such as biodegradable plastics and low-carbon and decarbonization-related products |

◎ Mass production of Kaneka biodegradable polymer Green Planet™ ◎ Promoting research and development to produce the Kaneka biodegradable polymer Green Planet™ from carbon dioxide and hydrogen

|

| Market | Increased demand for biomass-based resins and decreased demand for fossil-based plastics | ||

| Technological | Low-carbon trends affecting raw material and energy sources | ● Fluctuations in fuel costs due to price changes in crude oil, etc. |

◎ Early fuel conversion of private power generator facilities

|

| ● Increase in purchase and sales fares due to the introduction of decarbonization technology in transport vehicles and the transfer of credit purchase costs |

|

||

| Market | Increased demand for renewable energy, energy networks, and energy-saving-related products | ● Growing demand for materials for ZEB and ZEH |

◎ Enhancement and expansion of products related to solar power generation

|

| Acute | Impact of extreme weather events on our manufacturing sites and supply chain | ● Events caused by flooding due to heavy rainfall or water shortages. Such events could include production stoppages at our factories, supply chain disruptions, etc., leading to lost sales opportunities and increased building damage |

|

| Increased demand for building materials in preparation for disasters caused by extreme weather events | ● Higher sales of building materials products that curb damage caused by weather disasters |

|