Environment

Climate Change Initiatives

- Initiatives for Climate Change: Information Disclosure in Line with TCFD

- Energy Conservation Efforts

- Actions to Reduce CO2 Emission Intensity

- GHG Emissions from Business Activities throughout the Supply Chain

- Investments in Energy-Efficient Facilities

- Eco-Friendly Products

- Energy-Efficiency Initiatives in Logistics

- Response to the Act on Rational Use and Proper Management of Fluorocarbons of Japan

To address global warming, we are working to promote energy conservation and reduce CO2 emissions through a range of measures, including our own environmental capital investment program.

We are implementing life cycle assessment (LCA) for our main products and intend to successively expand the range of products covered going forward. We are also working to introduce carbon-life cycle analysis (cLCA) and indirect GHG emissions calculation. Carbon-life cycle analysis (cLCA) uses an LCA-based quantitative evaluation to calculate the contribution to GHG emissions reduction relative to comparable products. Indirect GHG emissions calculation covers business activities throughout the supply chain (Scope 3 emissions).

Initiatives for Climate Change: Information Disclosure in Line with TCFD

With people and technology growing together into creative fusion, we will break fresh ground for the future and tie in to explore New Values. We are also committed to challenge the environmental issues of our planet and contribute to upgrading the quality of life. Guided by this corporate philosophy, Kaneka Group will leverage its products and services to globally offer useful solutions to the issue of climate change, and will fulfill its social responsibilities regarding the various climate change-related impacts associated with the production and distribution processes. As part of this, we expressed our support for the recommendations of the Task Force on Climate-related Financial Disclosures (TCFD) in March 2021.

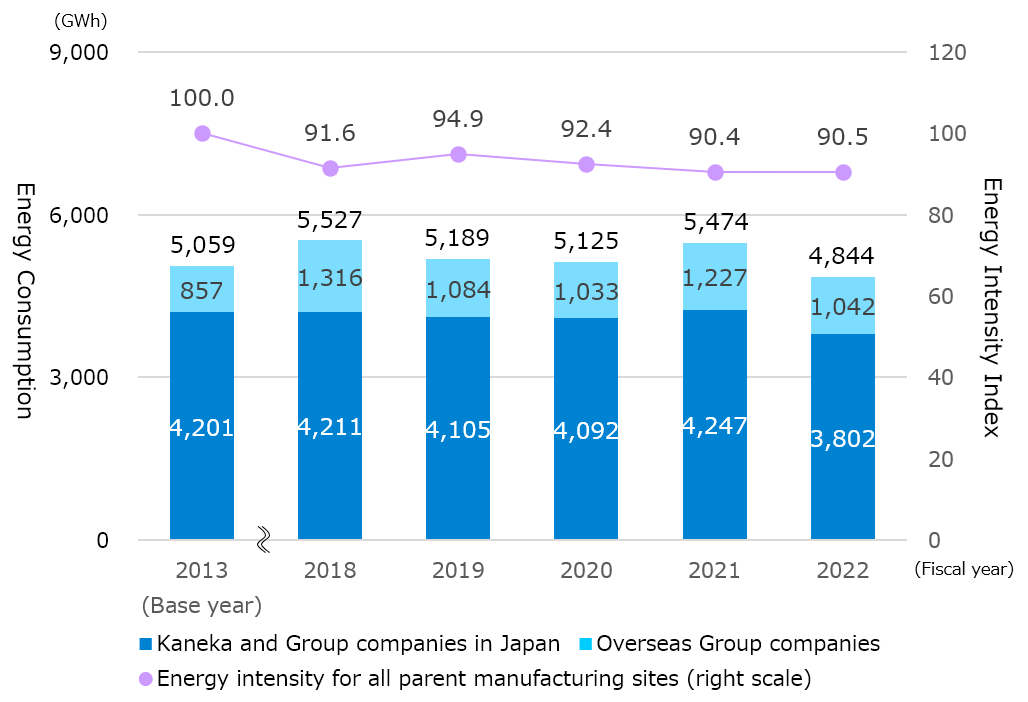

Energy Conservation Efforts

We are engaged in energy conservation activities, using the energy intensity index as an indicator for management.

The energy intensity index for all parent manufacturing sites in fiscal 2023 was 96.3, an increase of 6.3% from the previous fiscal year. The average rate of change over the five-year period was an increase of 0.4%, which did not reach our goal of an annual average decrease of 1%.

Kaneka Group used 5,301 GWh, an increase of 9.4% from the previous fiscal year, mainly due to an increase in production volume.

For details, please refer to “Calculation Methods for Data of Indicators Related to Environment”.

Targets and Performance/Evaluation

| Fiscal 2023 target | Fiscal 2023 performance | Evaluation | |

|---|---|---|---|

| Energy intensity index | Average annual reduction of 1% or more | 96.3 (all parent manufacturing sites) (106.3% year-on-year change) | × |

| Five-year average change rate 100.4% | × | ||

Energy Consumptions and Energy Intensity Index

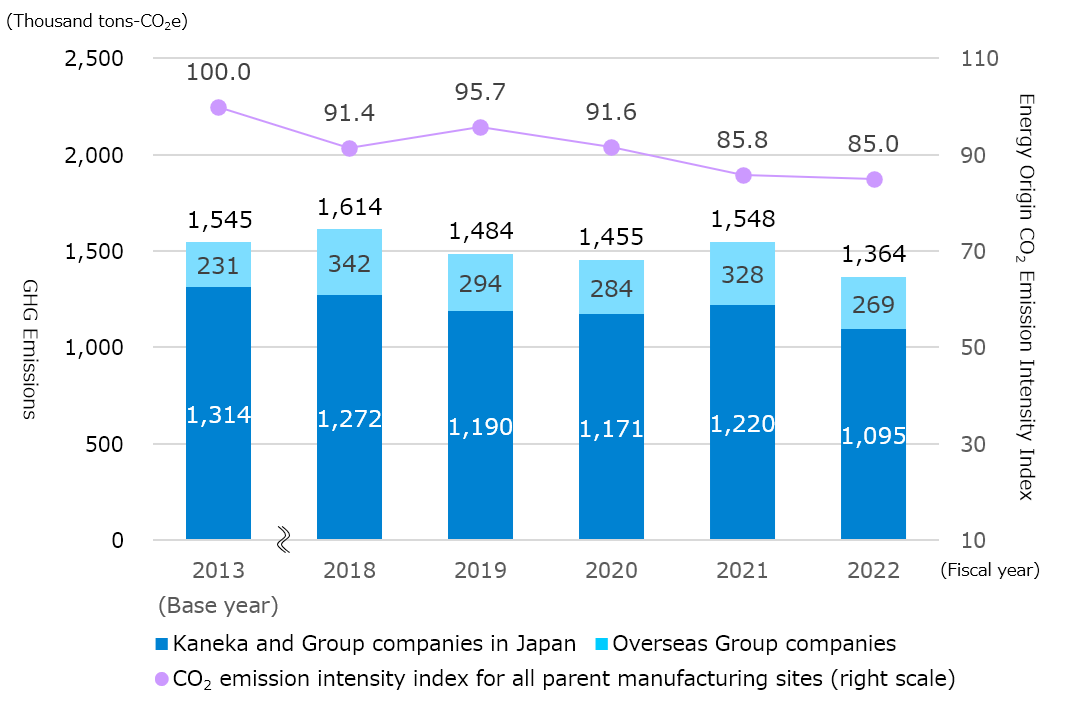

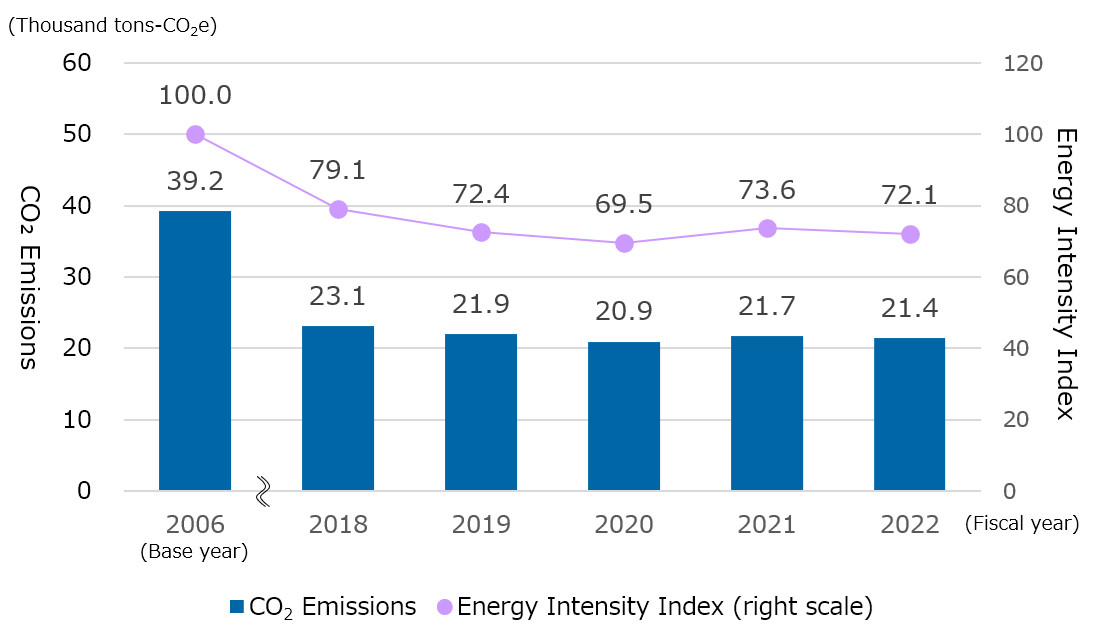

Actions to Reduce CO2 Emission Intensity

We are working to reduce CO2 emission intensity, using a CO2 emission intensity index as an indicator for management, based on CO2 emissions from energy consumption associated with production activities.

In fiscal 2023, the index for all parent manufacturing sites was 83.3, achieving our fiscal 2023 target of 90.4 (toward a fiscal 2030 target of 84.3). GHG emissions for the Kaneka Group as a whole were 1,513 thousand tons-CO2e, up 10.9% from the previous fiscal year, due in part to increased production volume. Going forward, we will continue to take energy saving actions and, based on our strategy for carbon neutrality, will work to reduce GHG emissions by means of actions such as streamlining production processes through innovation and switching to alternative fuels.

Targets and Performance/Evaluation

| Fiscal 2023 target | Fiscal 2023 performance | Evaluation | |

|---|---|---|---|

| CO2 emission intensity index | Average annual reduction of 1% or more (fixed emissions factor) Estimated fiscal 2023 performance 90.4 (fiscal 2030 target 84.3) |

83.3 (all parent manufacturing sites) | ◎ |

GHG Emissions and Energy Origin CO2 Emission Intensity Index

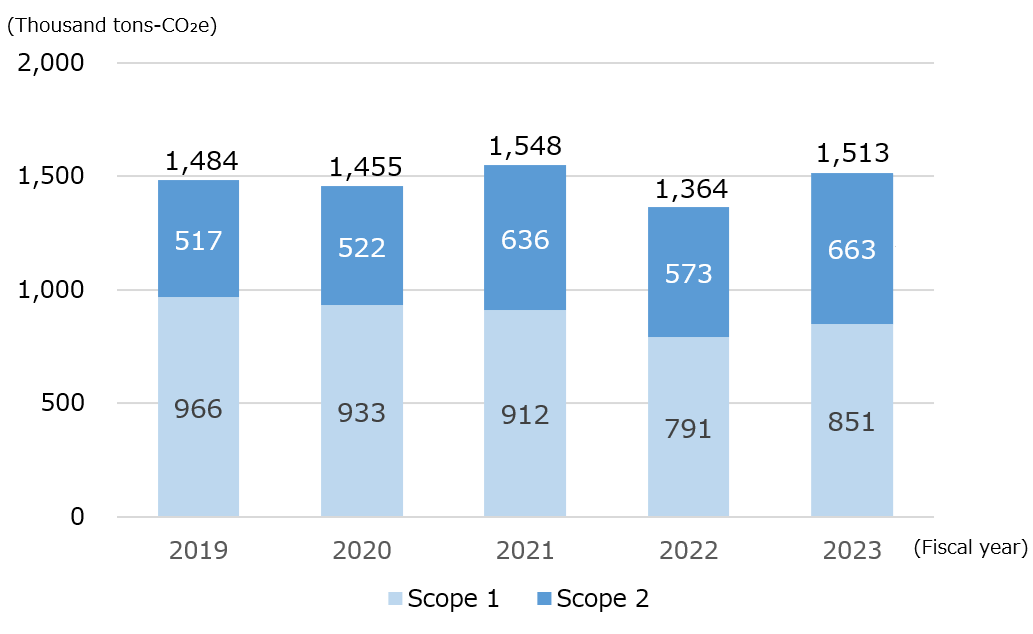

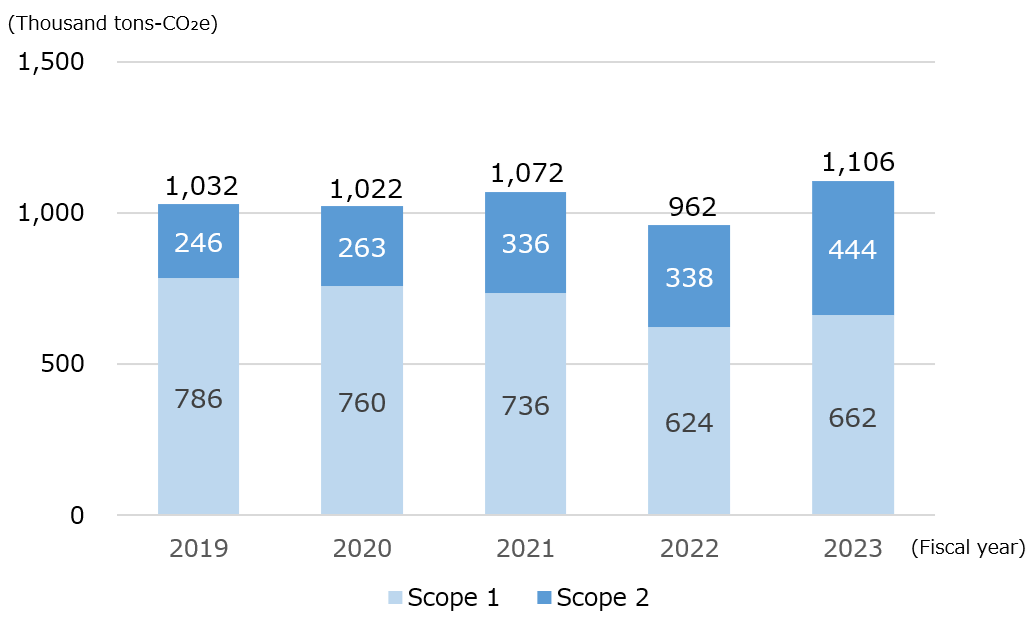

Scope 1 and 2 Emissions (Kaneka Group)

Kaneka Group Scope 1 and 2 Emissions (Fiscal 2023)

(Thousand tons-CO2e/year)

| Kaneka | Group companies in Japan | Overseas Group companies | Total | |

|---|---|---|---|---|

| Scope1 direct emissions(*1) |

662 | 64 | 125 | 851 |

| Scope2 indirect emissions from purchased or acquired electricity, steam, heat and cooling (*2) |

444 | 66 | 152 | 663 |

| Total | 1,106 | 130 | 277 | 1,513 |

Note: Amounts reported here may not fully match, due to rounding.

*1 Non-energy CO2 emissions and CO2-equivalent of methane, N2O, and NF3 emissions are included.

*2 Scope 2 emissions calculated using the location-based method were 464 thousand tons CO2e for Kaneka and 69 thousand tons CO2e for Group companies in Japan. For overseas Group companies, Scope 2 emissions were the same calculated using location-based and market-based methods.

Scope 1 and 2 Emissions (Kaneka)

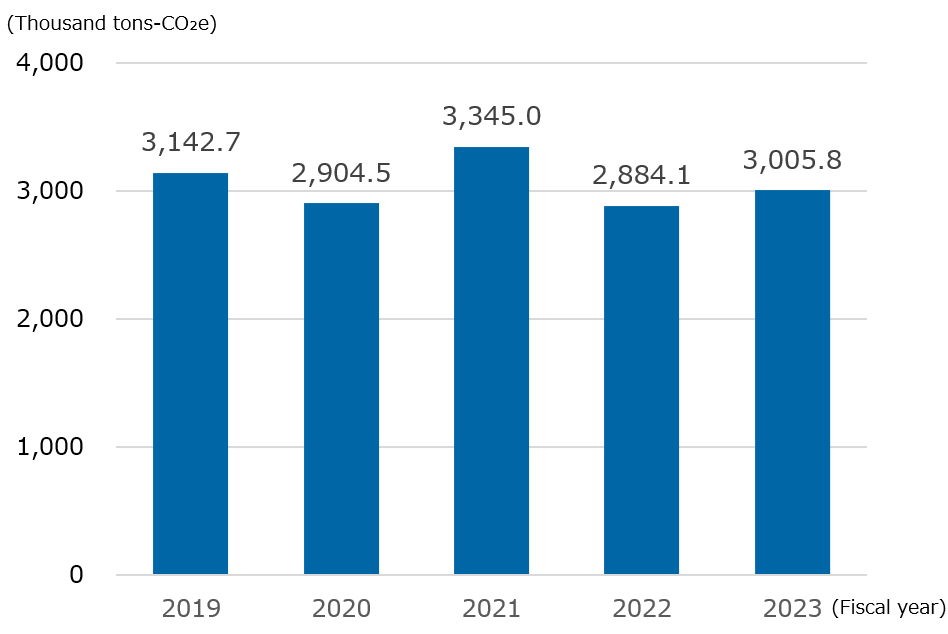

GHG Emissions from Business Activities throughout the Supply Chain

We have calculated indirect GHG emissions (Scope 3) associated with our business activities through supply chains. Kaneka has thus far based its calculation of Scope 3 emissions on Kaneka, the parent company. Starting from fiscal 2022 results, we have started to calculate some categories of Scope 3 emissions on a consolidated basis. A dash (“-”) in the table indicates that data that has not been calculated.

Kaneka Group Scope 3 Emissions Calculated by Category (Fiscal 2023)

(Thousand tons-CO2e/year)

| Category | Kaneka | Group companies in Japan |

Overseas Group companies |

Total | |

|---|---|---|---|---|---|

| 1 | Purchased goods/services | 1,817.0 | - | - | 1,817.0 |

| 2 | Capital goods | 49.3 | 22.7 | 29.3 | 101.3 |

| 3 | Fuel-and energy-related activities not included in Scope 1 or Scope 2 | 159.1 | 24.9 | 78.9 | 262.9 |

| 4 | Upstream transportation and distribution | 20.9 | - | - | 20.9 |

| 5 | Waste generated in operations (*3) | 5.2 | 10.1 | 7.7 | 23.0 |

| 6 | Business travel | 7.3 | 0.5 | 0.4 | 8.2 |

| 7 | Employee commuting | 1.3 | 1.5 | 1.2 | 4.1 |

| 8 | Upstream leased assets | 0.0 | - | - | 0.0 |

| 9 | Downstream transportation and distribution | (*4) | (*4) | (*4) | (*4) |

| 10 | Processing of sold products | (*4) | (*4) | (*4) | (*4) |

| 11 | Use of sold products | (*5) | (*5) | (*5) | (*5) |

| 12 | End-of-life treatment of sold products | 539.3 | 104.6 | 280.3 (*6) | 924.2 |

| 13 | Downstream leased assets | 0.02 | - | - | 0.02 |

| 14 | Franchises | (*7) | - | - | - |

| 15 | Investments | 406.3 | - | - | 406.3 |

| Total of Scope 3 emissions | 3,005.8 | 164.3 | 397.8 | 3,567.9 | |

Note: Amounts reported here may not fully match, due to rounding.

*3 CO2 emissions from waste transportation are not included in category 5 but are calculated in category 4.

*4 GHG emissions for this category were not calculated because we were unable to determine a rational calculation method due to the high percentage of intermediate products.

*5 Some products generate emissions when used. However, since it was confirmed that this represented less than 0.1% of total Scope 3 emissions, such emissions were excluded from the calculation range.

*6 Kaneka Medical Vietnam Co., Ltd. is not included in the calculation because its products have not been converted to weight.

*7 GHG emissions for this category were not calculated because we have no franchise stores.

Scope 3 Emissions (Kaneka) (*8)

*8 Actual Category 5 figures for and prior to 2022 have been revised following a revision of the waste plastic processing classification and the deduction of CO2 emissions related to waste transportation over previous fiscal years.

Investments in Energy-Efficient Facilities

To continue reducing energy intensity and CO2 emission intensity, we are implementing our own environmental capital investment program, with an annual budget of 300 million yen (the budget was 200 million yen until fiscal 2020 but we increased it in fiscal 2021 to strengthen our climate change response). Investments are for small and medium investments that have a relatively long payback period, through activities in three areas – global warming prevention, effective use of resources, and environmental impact reduction – that are priorities in Kaneka’s environmental management program. In fiscal 2023 we continued allocating a large portion of this fund to projects that address climate change, including broader initiatives such as visualizing energy consumption. We will continue to use this investment program effectively to promote energy conservation and GHG emission reduction activities.

Results of Our Own Environmental Capital Investment Program

| Fiscal Year | Investments (million yen) | Number | Reduced CO2 Emission of the Year |

|---|---|---|---|

| 2019 | 200 | 29 | 1,227 tons-CO2 |

| 2020 | 200 | 27 | 1,010 tons-CO2 |

| 2021 | 300 | 36 | 1,757 tons-CO2 |

| 2022 | 300 | 30 | 2,319 tons-CO2 |

| 2023 | 300 | 38 | 3,692 tons-CO2 |

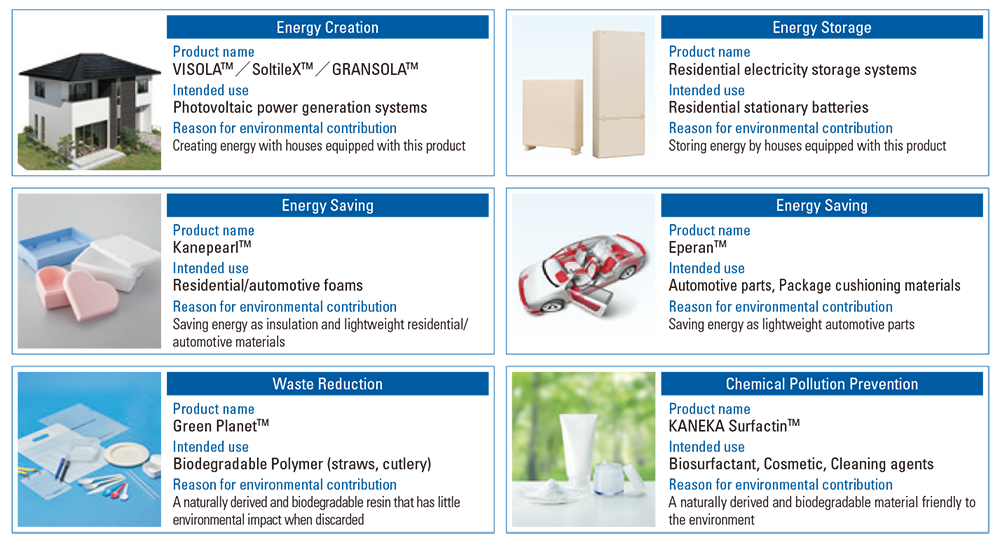

Eco-Friendly Products

Kaneka Group has focused on eco-friendly management since fiscal 2017. We have enhanced and expanded our lineup of eco-friendly products, which we define as products that help reduce the burden on the natural environment compared to conventional products at the customer use, disposal, and recycling stages (see the table below).

Eco-friendly products have been defined as follows.

| Type of Environmental Contribution | Qualitative Definition |

|---|---|

| GHG Reduction | Products reducing greenhouse gas (GHG) emissions |

| Energy Saving | Products lowering energy consumption |

| Energy Creation | Products creating energy |

| Energy Storage | Products storing energy |

| Waste Reduction | Products reducing waste |

| Resource Saving | Products achieving resource savings |

| Biomass | Products (derived from non-fossil materials) reducing reliance on fossil materials |

| Water Resources | Products saving water and improving the water environment |

| Chemical Pollution | Products preventing chemical pollution |

| Biodiversity | Products conserving biodiversity |

| Intermediate Materials | Intermediate materials essential to ensuring that finished products contribute to the environment |

| Disaster Control | Products helping disaster prevention and preparedness and reducing environmental impacts during a disaster |

| Adaptive Contribution | Products adapting to global warming |

Energy-Efficiency Initiatives in Logistics

To achieve an annual 1% reduction in energy intensity and a continuation of 1% improvement in five-year average energy intensity as a specified consigner under the amended Act on Rational Use of Energy, we continued working towards implementing modal shifts, promoting joint distribution, and improving cargo load ratios.

In fiscal 2023, by continuing to implement modal shifts and making use of various subsidies, we achieved a reduction of 0.5 thousand tons in CO2 emissions. However, due to a decrease in rail transport and a rise in the share of truckload (regional services) and small parcel deliveries, the energy intensity index increased by 1.9% compared to the previous year.

We continue to promote modal shifts, including the use of rail transport, and work on improving load ratios to enhance transportation efficiency as we strive to reduce our CO2 emissions.

CO2 Emissions and Energy Intensity Index from Logistics (Kaneka)

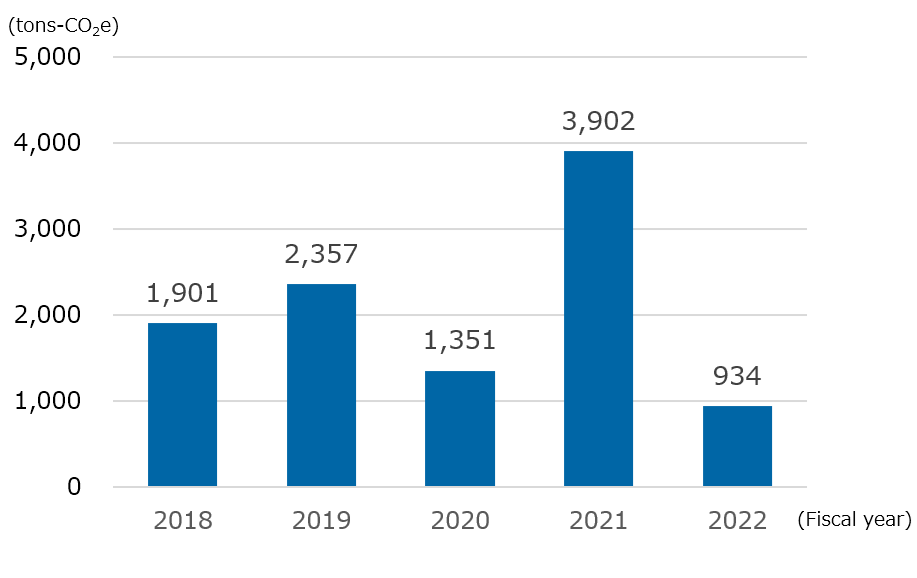

Response to the Fluorocarbons Emission Control Law

Complying with the Act on Rational Use and Proper Management of Fluorocarbons in Japan, we are promoting the replacement of aging equipment that use specified fluorocarbons as well as strengthening our management of equipment.

The estimated leakage of fluorocarbons in fiscal 2023 at Kaneka was 995 tons-CO2e. While this marked an increase of 61 tons-CO2e from the previous year, we met our target for reducing the estimated leakage of fluorocarbons to 1,000 tons-CO2e or less for the second consecutive year. At Group companies in Japan, there were no estimated leakage of fluorocarbons exceeding 1,000 tons-CO2e. We will continue to systematically update aging equipment, selecting equipment with low global warming potential (*9) and green refrigerant. We will also reduce the leakage of fluorocarbons by inspecting equipment to detect and eliminate fluorocarbon leaks at an early stage.

These initiatives and information dissemination have been recognized with an A rating in the Fluorocarbon Countermeasure Rating 2023 by the Japan Refrigerants and Environment Conservation Organization (JRECO) (*10). We have been awarded an A rating for three consecutive years in the organization’s compliance status survey for the Act on Rational Use and Proper Management of Fluorocarbons.

*9Global warming potential is a figure that shows, on the basis of carbon dioxide, how other greenhouse gases have the property of causing global warming.

*10This survey evaluates whether companies understand and recognize the Act on Rational Use and Proper Management of Fluorocarbons, and whether they are taking action and disseminating information. The Japan Refrigerants and Environment Conservation Organization (JRECO) conducts an online search of each company’s integrated reports and sustainability reports, comprehensively assesses their efforts regarding fluorocarbons, and annually announces the Fluorocarbon Countermeasure Rating.

Estimated Leakage of Fluorocarbons (Kaneka)