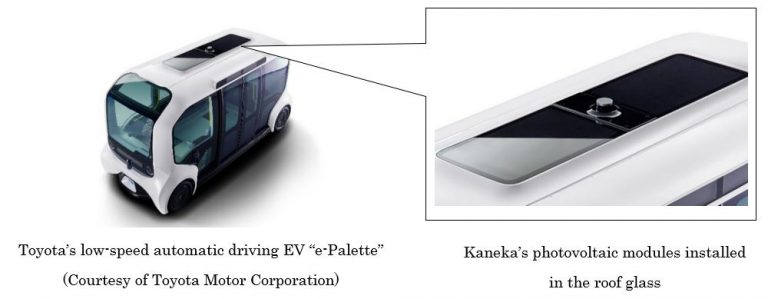

Kaneka's high-performance photovoltaic modules adopted in Toyota's low-speed automatic driving EV "e-Palette"

July 31, 2020

Crystalline silicon photovoltaic modules (heterojunction back-contact-type*1) developed by Kaneka Corporation (Headquarters: Minato-ku, Tokyo; President: Minoru Tanaka) have been adopted for use in the roof glass of Toyota Motor Corporation's low-speed automatic driving EV "e-Palette".

This product utilizes Kaneka's crystalline silicon photovoltaic module technology that boasts the highest conversion efficiency in the world*2. Also, its back-contact configuration, which avoids front surface-side wiring, allows the design in a way similar to glass for automobiles. The high conversion efficiency and the excellent design flexibility of our unique technology have been recognized and adopted.

Because Kaneka's in-vehicle photovoltaic module can be designed in a curved shape, it can be installed in the car body. Kaneka will continue to strengthen its photovoltaic module offerings for vehicles, which contribute to having longer driving distances and reducing CO2 emissions, and aim to have them further adopted in EVs and hybrid cars.

- Crystalline silicon photovoltaic modules that combine both heterojunction and back-contact technologies. Heterojunction technology is a technology which binds semiconductor materials with different physical properties, and it can improve conversion efficiency through defect reduction by bringing together crystalline silicon and amorphous silicon, and a combination of materials that can convert light with different wavelengths into electricity. Back-contact technology has the electrodes for electricity extraction only on the back side of a solar cell, and by keeping the electrodes on the back side the light receiving area can be increased, which improves the conversion efficiency and also the flexibility of designs.

- As a crystalline silicon solar cell it achieves the world's highest conversion efficiency of 26.7%. (Research by Kaneka.)