Feature of KANE ACE™ MX

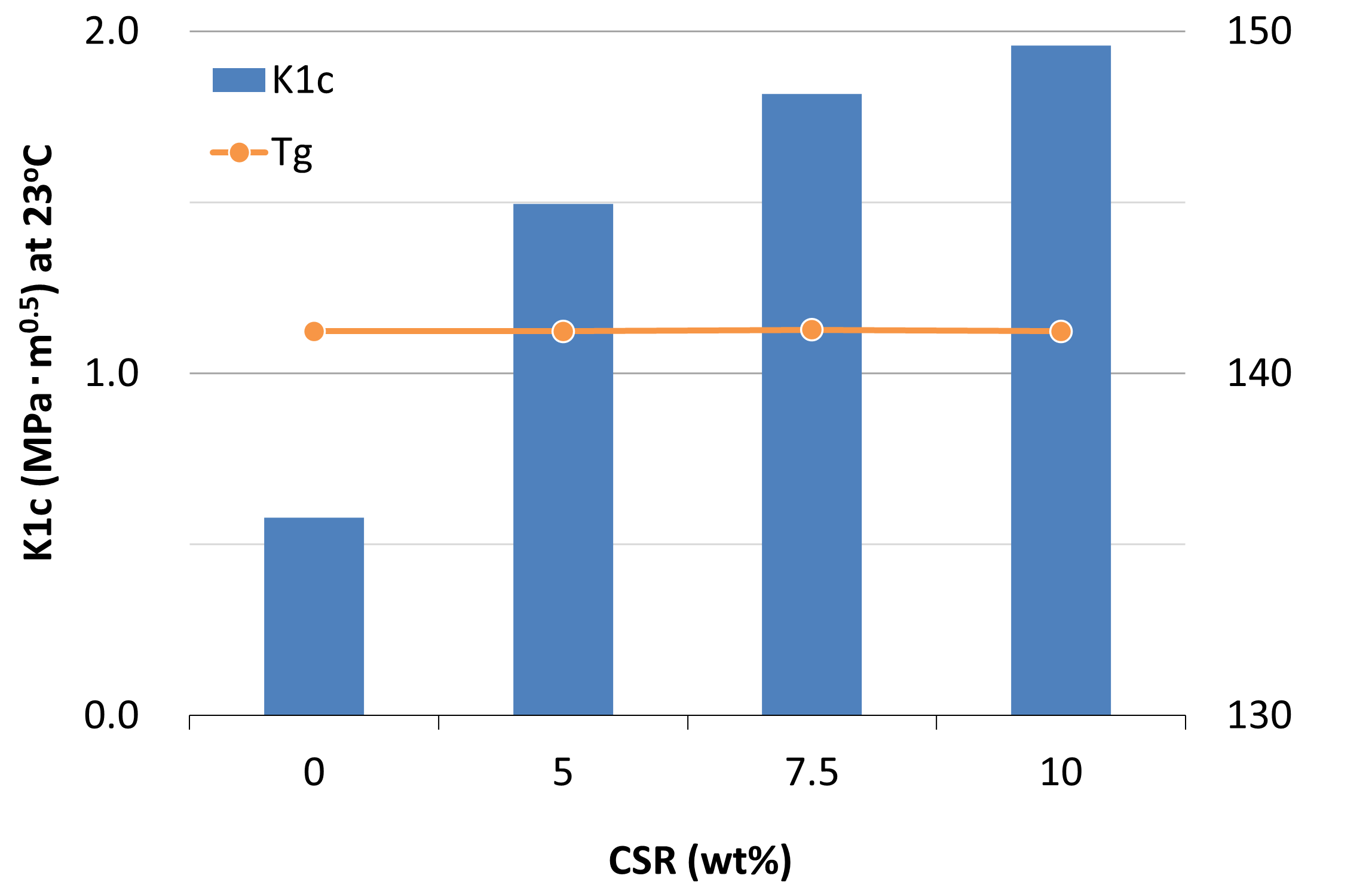

- Improves fracture toughness and adhesive properties, etc., while maintaining thermal properties

- Can be dispersed uniformly without cumbersome/time-consuming mixing or dispersion process

- Applicable for wide variety of thermosetting resins, curatives and various cure conditions

- Gives stable sea-island morphology and therefore high reproducibility

Applications

- Adhesive (automotive, aerospace and industrial structural adhesives, bonding paste for wind turbines)

- Composite material (pressure vessels, auto parts, aerospace, pipes, sporting goods, wind turbine blades)

- Others (E&E encapsulants, casting materials, molding compounds, 3D printing inks, CCL, etc.)

Solutions

- Enhances impact resistance and fracture toughness of cured products without depression of thermal properties

- Improves fatigue resistance and heat shock resistance by stress relaxation

- Reduces defect rate and improve manufacturing yield by preventing cure-related cracks

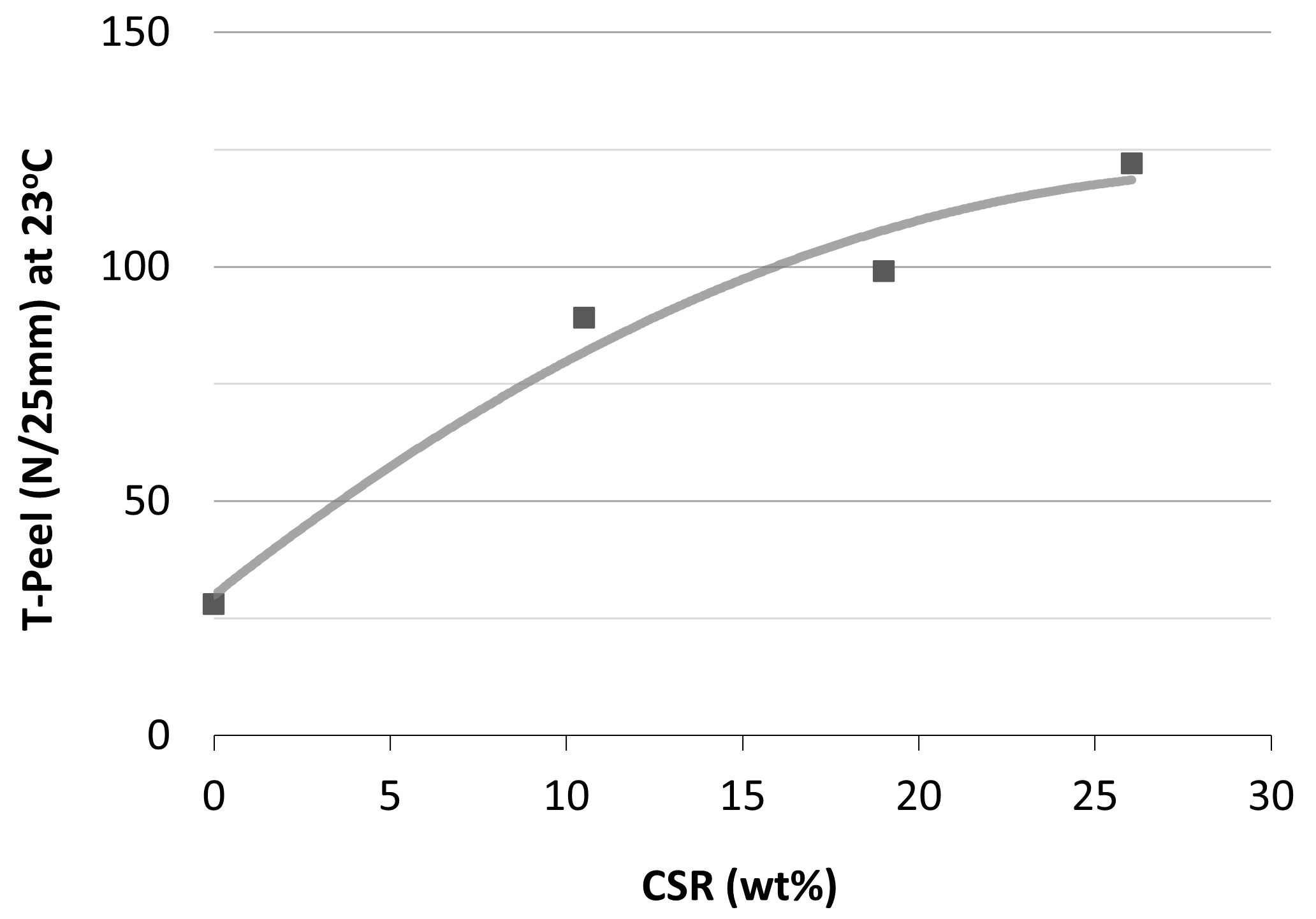

- Enhances adhesive properties and crash resistance under lower temperature

- Shows stable performance regardless of cure conditions

- Saves time-consuming process for mixing powder material into liquid resins

Example of Grades

Bis-A Epoxy

| Product | CSR | CSR Content | Viscosity [mPa.s@50ºC] |

|---|---|---|---|

| MX-125 | SBR | 25% | 5,500 |

| MX-153 | PBd | 33% | 17,000 |

| MX-257 | 37% | 18,000 | |

| MX-150 | 40% | 16,000 | |

| MX-154 | 40% | 25,000 | |

| MX-160 | 45% | 25,000 | |

| MX-962 | Silicone | 25% | 3,000 |

Bis-F Epoxy

| Product | CSR | CSR Content | Viscosity [mPa.s@50ºC] |

|---|---|---|---|

| MX-136 | PBd | 25% | 2,500 |

| MX-267 | 37% | 7,000 | |

| MX-965 | Silicone | 25% | 1,500 |

TGMDA based Tetra-functional Epoxy

| Product | CSR | CSR Content | Viscosity [mPa.s@50ºC] |

|---|---|---|---|

| MX-414 | PBd | 25% | 30,000 |

TGPAP based Tri-functional Epoxy

| Product | CSR | CSR Content | Viscosity [mPa.s@50ºC] |

|---|---|---|---|

| MX-451 | SBR | 25% | 12,000 |

Cycloaliphatic Epoxy

| Product | CSR | CSR Content | Viscosity [mPa.s@50ºC] |

|---|---|---|---|

| MX-553 | PBd | 30% | 3,000 |

| MX-555 | 40% | 4,500 |

Unsaturated Polyester Resin

| Product | CSR | CSR Content | Viscosity [mPa.s@50ºC] |

|---|---|---|---|

| MX-010 | PBd | 40% | 6,000 @ 25ºC |

PPG MW 1000

| Product | CSR | CSR Content | Viscosity [mPa.s@50ºC] |

|---|---|---|---|

| MX-710 | PBd | 40% | 4,000 @ 25ºC |

PPG MW 400

| Product | CSR | CSR Content | Viscosity [mPa.s@50ºC] |

|---|---|---|---|

| MX-714 | PBd | 40% | 2,000 @ 25ºC |

- These are typical but not guaranteed values.

Related information

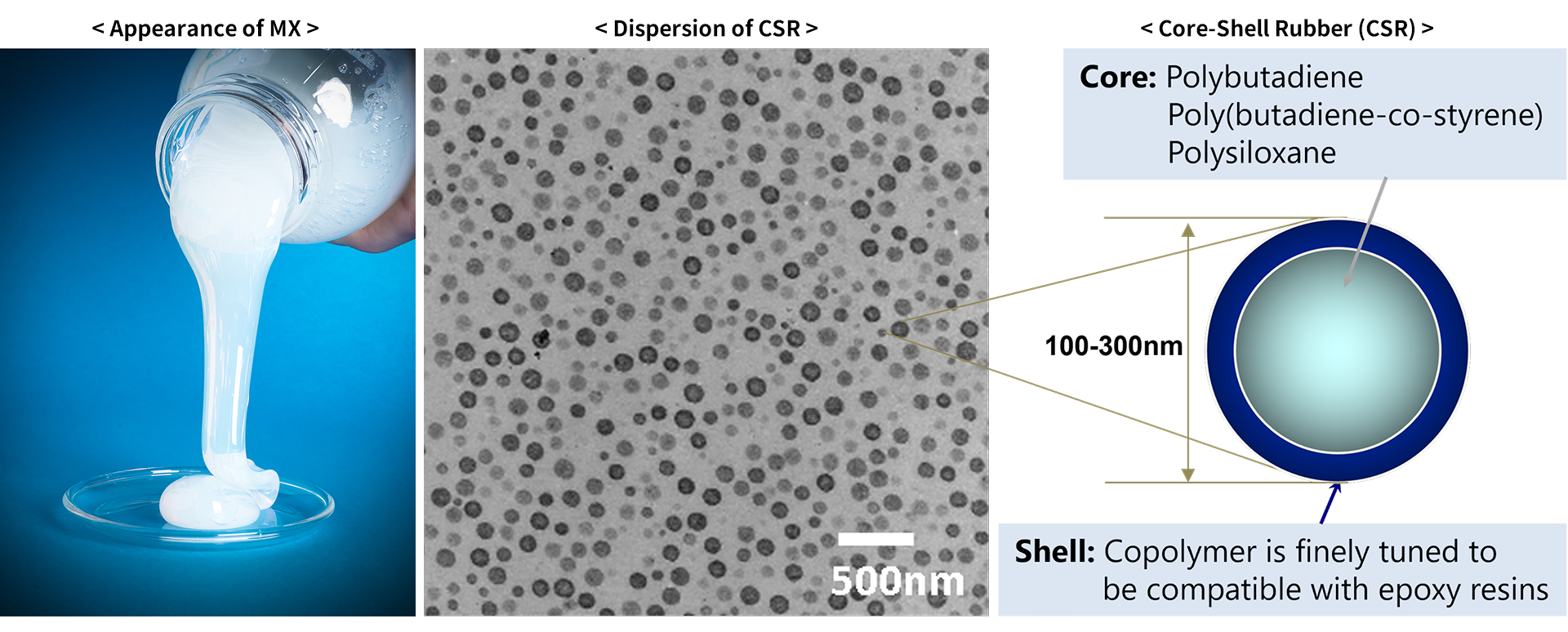

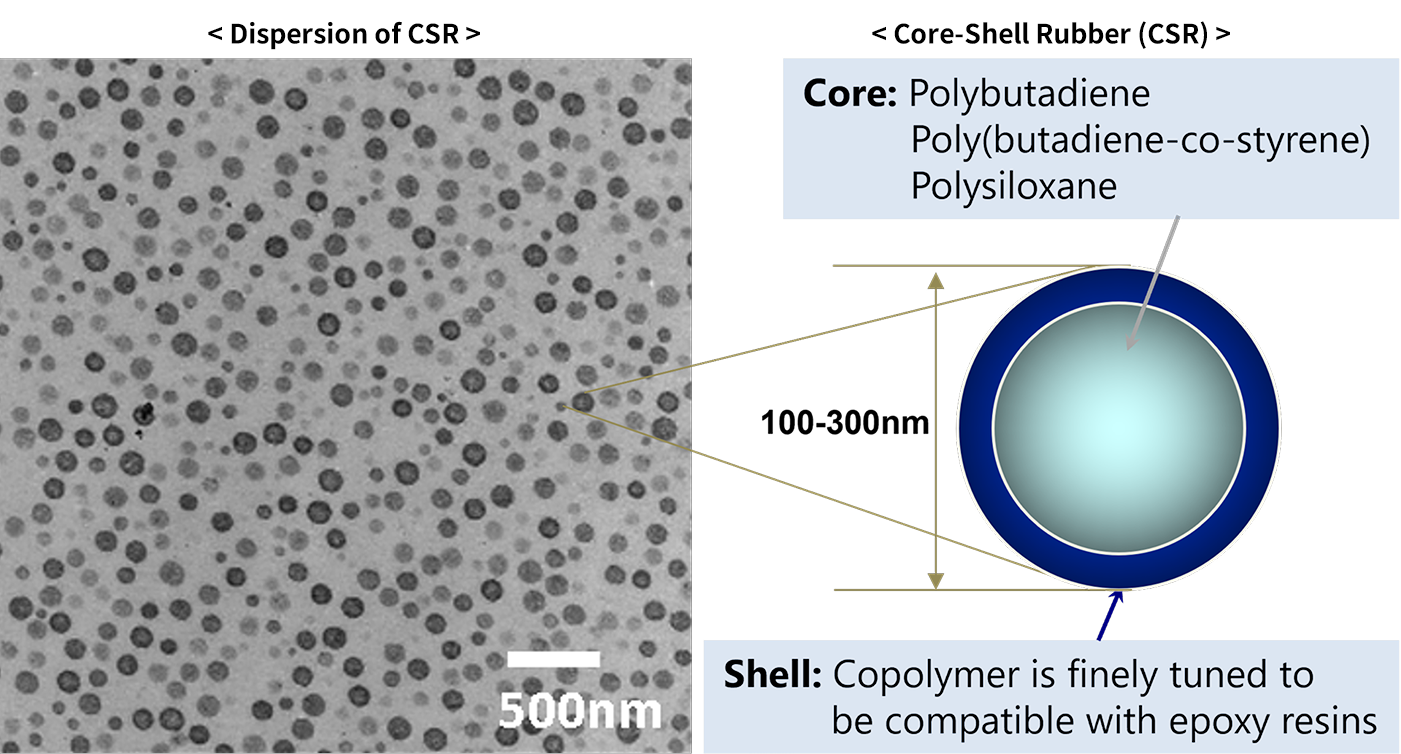

Core-Shell Rubber (CSR)

Fracture Toughness

Formulation: DGEBA/CSR/MTHPA

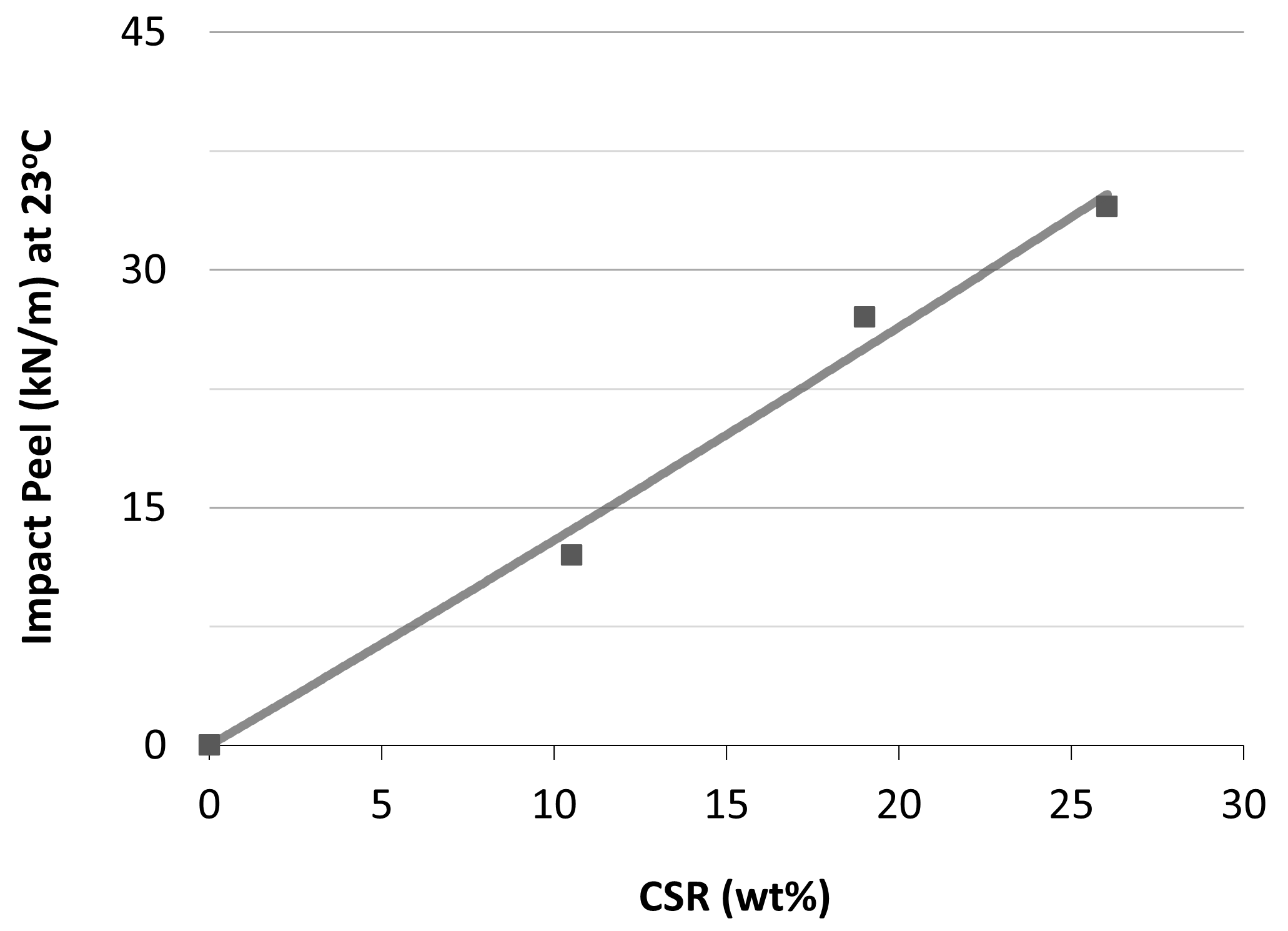

Adhesive property

Improve adhesive properties of 1 component epoxy adhesive

Formulation: DGEBA/CSR/DICY/Fillers