Safety / Quality

Management Approach

Basic Policy

Placing the top priority for management on safety, we have established the Basic Policy on Safety, under which all employees as well as all persons working at the Kaneka Group and our partner companies work to create safe and healthy workplaces , pursuing the goal of no accidents and no disasters.

As for product quality, aiming to benefit society and satisfy customers through a stable supply of safe and reliable products, Kaneka Group has set Quality Management Regulations to ensure thorough day-to-day quality control and product safety at all stages, from product design and development to delivery to customers.

Policy

Basic Policies for Responsible Care

- Protect the natural ecosystem and reduce environmental impact

Focusing on the impact of corporate activities on the global environment and the ecosystem, we endeavor to reduce environmental impact and promote resource conservation and energy saving throughout the lifecycle of products. - Offer safe products and information

We endeavor to offer products that are safe to distribute and use, and to provide adequate information on the products such as instructions on how to use and handle products correctly. - Develop products and technologies in consideration of the environment and safety

Upon the development of new products, we give consideration to the environment and safety throughout the lifecycle of the products to the greatest extent possible, and endeavor to develop products and technologies with low environmental impact. - Reduce waste and promote the recycling of plastics

We reduce waste associated with manufacturing and its processes. We actively develop technologies for the adequate disposal or recycling of plastic waste concerning our products in cooperation with relevant industries, and endeavor to dispose of and recycle waste in a proper manner. - Enhance process safety, disaster‒prevention, and occupational safety and health

Safety and disaster prevention constitute the foundations of the local community’s trust, and occupational health and safety are issues that need to be fulfilled by chemical companies. We persistently strive to make improvements in these areas. - Win public confidence

From the management to every employee, all our members shall act in compliance with laws, regulations, standards, etc. relating to environment and safety both at home and abroad. Our approach to Responsible Care as such shall be publicized accurately to the public, in hope of rightfully gaining public recognition and confidence.

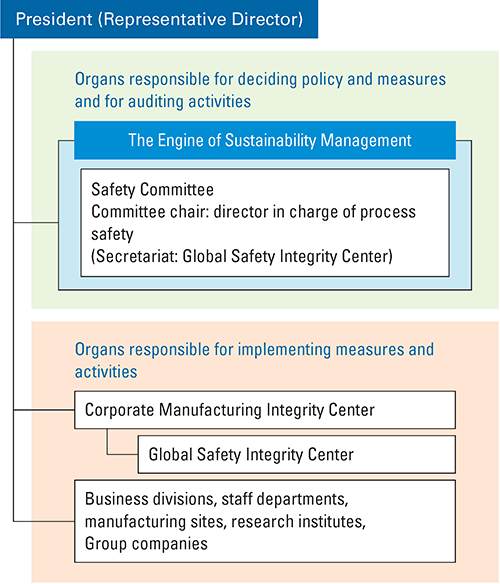

Promotion System

Established under the Engine of Sustainability Management, the Safety Committee sets policies and goals related to occupational safety, process safety, and disaster prevention and to check their implementation and progress.

As set out in our Basic Safety Policies, our Zero Accident Principles, and Kaneka Group Code of Conduct, we prioritize safety above all else, observe the principles of safety, and work to ensure that safe practice is taken on board and strictly adhered to. In this way we seek to guarantee safety and peace of mind through stable day-to-day manufacturing operations. In his greetings at New Year and on the yearly anniversary of our foundation, the president delivers a related message directly to employees.

Message from the President

While continuing my plant tours, I have seen for myself how each plant is raising its safety awareness. You can see it taking hold on the shop floor.

When it comes to safety, there is no such thing as perfection.

We must always act with a sense of urgency. We must stay vigilant, focusing all our efforts on ensuring that throughout our operations we prioritize preventing accidents and disasters.

We must not overlook even the most minute signs of danger, instead working thoroughly to foresee and forestall accidents and problems.

Management will do its utmost to protect the lives, safety, and security of all our employees.

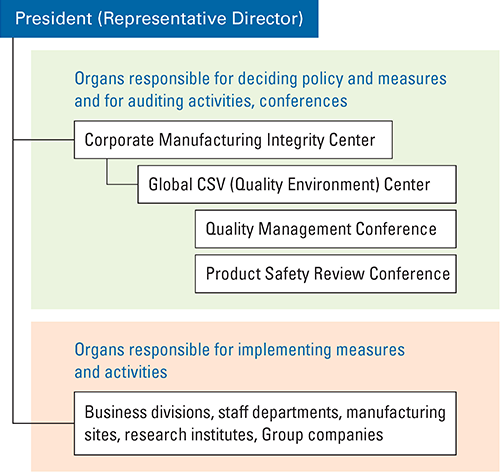

As for profuct quality, the Global CSV (Quality Environment) Center operates the Quality Management Conference and the Product Safety Review Conference. Through these bodies, we coordinate quality assurance activities throughout the Kaneka Group and drive quality management, including product safety assurance, at all stages from product design and development to raw material procurement, manufacturing, storage, and transportation. Each of our businesses undergoes regular third-party auditing and inspection based on ISO 9001 and other established standards and regulations. We also take steps in-house to enhance our quality management system and thereby raise product quality standards through ESG safety and quality inspections and internal audits.

Diagram of Promotion System

Safety

Quality

Targets and Performance

| Target | Fiscal 2022 performance | |

|---|---|---|

|

Strengthen process safety and disaster prevention Ensure occupational health and safety |

1)Ensuring the safety of equipment and processes

2)Fostering a safety culture 3)Readiness for emergency |

|

|

Process accidents Occupational accidents |

Zero accidents |

1)Process accidents: 7 2)Occupational accidents: Accidents resulting in lost time: 7; accidents not resulting in lost time: 10. |

*HAZOP (Hazard and Operability Studies): A hazard identification technique used for chemical plants.