Environment

Recycling Resources

Reducing Waste and Recycling Resources

To make effective use of limited resources, we seek to reduce and recycle industrial waste from our operations through the 3Rs (*1). We are also working toward achieving zero emissions (*2) at Kaneka and Group companies in Japan. In addition, we are working to use our resources effectively based on our target of improving the resource recycling rate (*3) for the Kaneka Group by 1% each year.

*1 3Rs refers to reduce, reuse and recycle.

*2 Zero emission definition by Kaneka: The final landfill waste must be less than 0.5% of the generated waste.

*3 Recycling rate: Volume of generated industrial waste that is recycled (total figure for industrial waste that is subject to reuse, recycling or heat recovery).

Reducing Industrial Waste Sent to Final Landfill and Increasing Recycling Rate

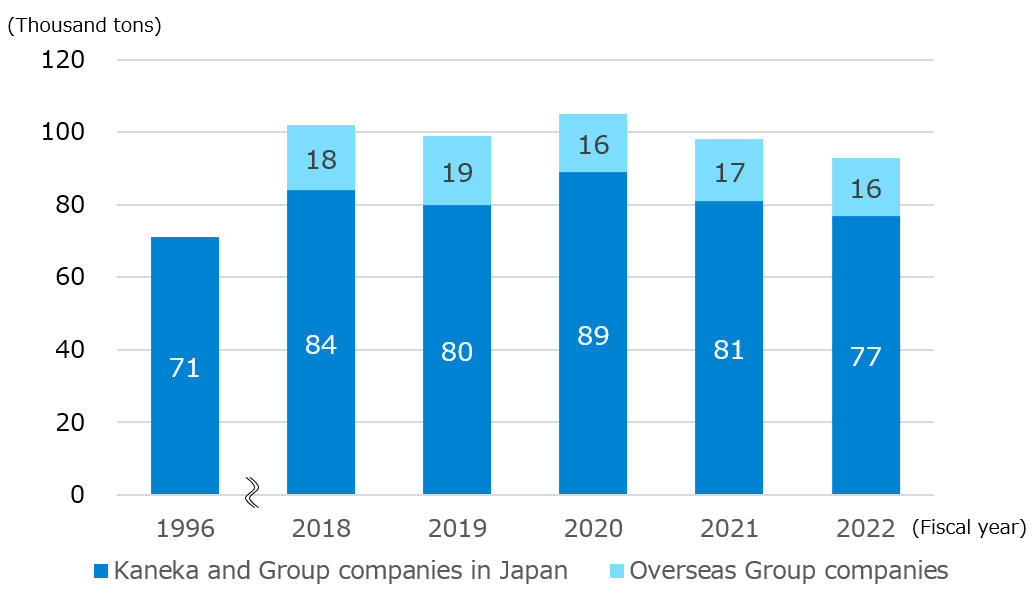

In fiscal 2023, Kaneka Group generated 95,411 tons of waste, an increase of 2,319 from the previous fiscal year. Although coal usage decreased from the previous year, the increase in soot and dust generation was mainly due to the use of coal with a high ash content.

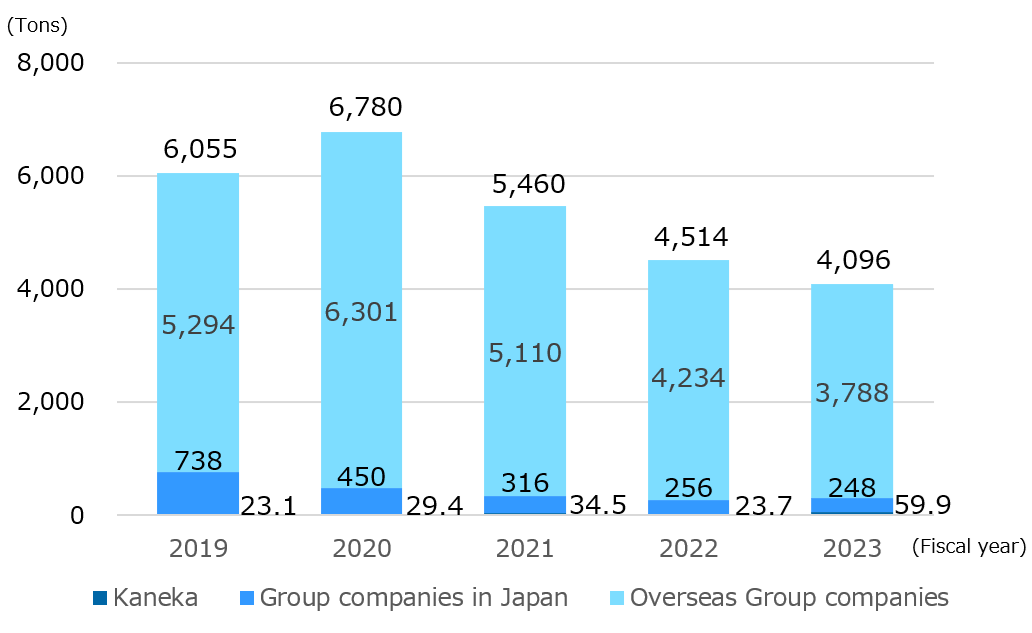

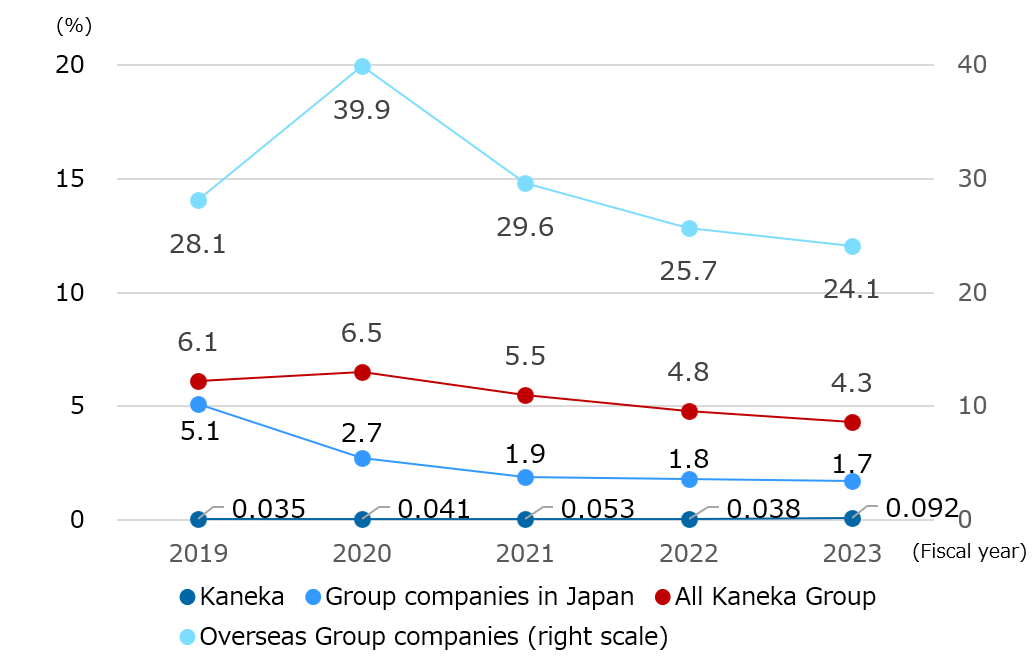

Kaneka’s final landfill volume was 11,549 tons in fiscal 1996. In fiscal 2023, it had decreased substantially to 59.9 tons. The final landfill rate was 16.33% in fiscal 1996, but dropped to 0.092% in fiscal 2023, marking 17 consecutive years of zero emissions for Kaneka. Additionally, with the final landfill rate for Kaneka and Group companies in Japan at 0.39%, we have achieved zero emissions.

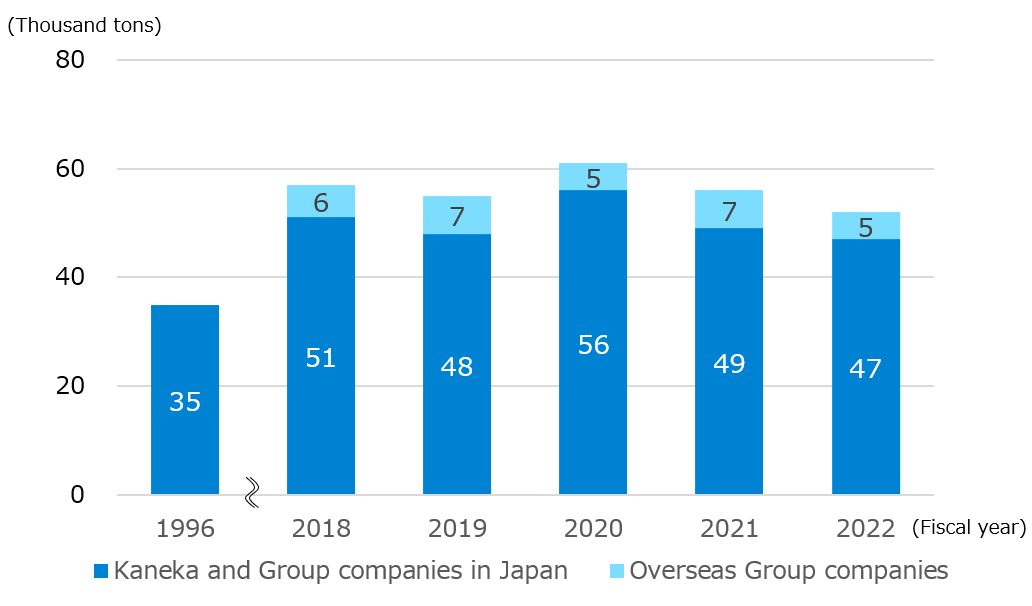

In fiscal 2023, Kaneka Group used external recycling of 54,567 tons of waste. The recycling rate of waste for the Kaneka Group improved 0.4% from fiscal 2022 to 57.2%.

Waste Generated

Volume of Waste Sent to Final Landfill

Rate of Waste Sent to Final Landfill

External Recycling

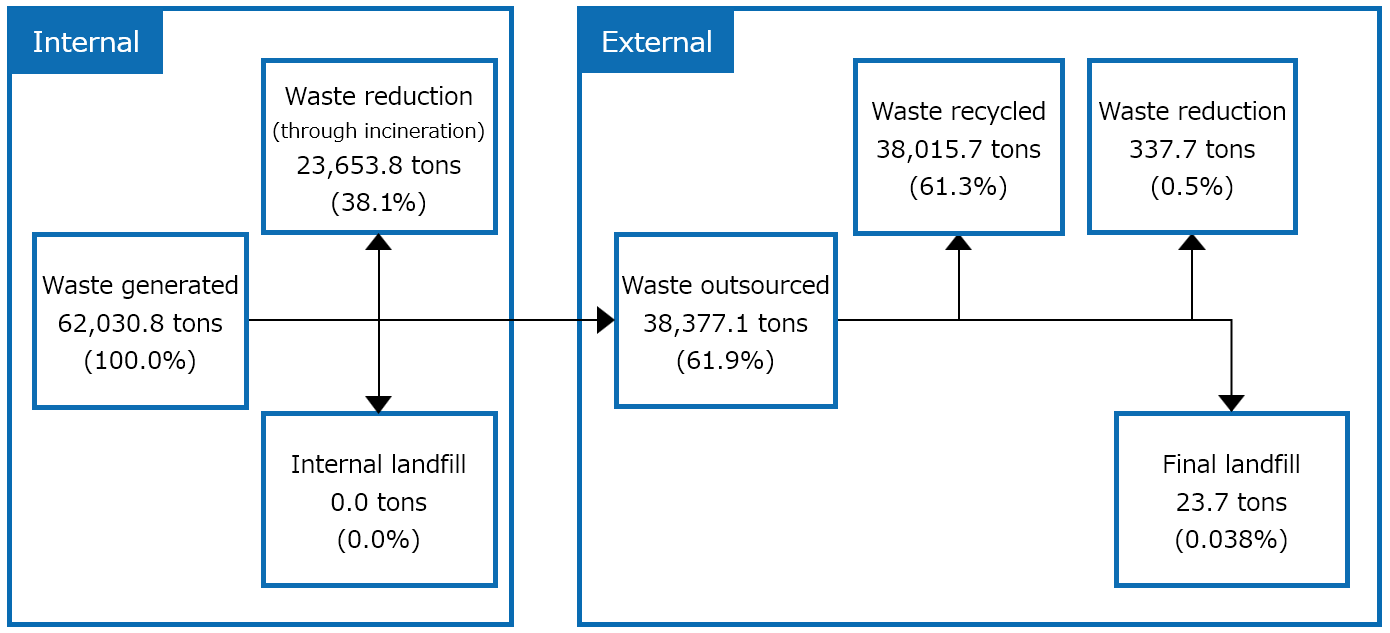

Waste Flow: From Generation to Landfill (Fiscal 2023 results at Kaneka)

Proper Disposal of Industrial Waste

We regularly visited waste disposal subcontractors and conducted surveys based on a checklist to ensure that waste was being properly processed by waste disposal subcontractors.

Response to the Plastic Resource Circulation Act

Status of Plastic Waste Generation and Reduction Targets

The amount of plastic waste generated, which was disposed of by outsourcing it as industrial waste was 1,715.8 tons at Kaneka (a 1.5% decrease from the previous year), 2,556.9 tons at Group companies in Japan (an 8.2% decrease from the previous year), and 4,272.7 tons on a consolidated basis in Japan (a 5.7% decrease from the previous year). Kaneka is working to reduce emissions and improve recycling rates with an initial goal of reducing the amount of plastic waste generated by 1% per year.

Status of Plastic Waste Generation (Fiscal 2023)

(Tons)

| Waste generated | Waste recycled | Waste incinerated | Landfill | Recycling rate (%) | |

|---|---|---|---|---|---|

| Kaneka | 1,715.8 | 1,572.6 | 114.2 | 29.0 | 91.7 |

| Group companies in Japan | 2,556.9 | 2,297.2 | 188.1 | 71.5 | 89.8 |

| Total | 4,272.7 | 3,869.9 | 302.4 | 100.5 | 90.6 |

Promotion of the 3Rs

We are taking actions across the company to reduce waste, recognizing that this ties into the maintaining and improving the natural environment in terms of saving resources, cutting costs, and reducing CO2 emissions, among other benefits.

Kaneka and Group companies in Japan are pursuing activities to reduce waste and recycle materials, mainly through a 3R approach at our various production facilities. We also facilitate continuous improvement activities through process analysis at Group companies in Japan using Material Flow Cost Accounting (MFCA).

3R Initiatives

Initiatives by Kaneka

We are continuously working on several initiatives to curb plastic waste emissions: (1) stabilizing manufacturing processes to improve yield; (2) process recycling of waste generated in manufacturing processes; (3) Reduction of emissions by reviewing the use of unnecessary plastic materials (4) examining measures to prevent scale generation during plastic manufacturing; and (5) thorough sorting to recycle plastic waste. We are also working to reduce waste by converting plastic waste into valuable materials and to recycling plastic waste that would otherwise be outsourced for incineration.

Initiatives by Group Companies in Japan

Group companies in Japan are actively working to reduce plastic waste emissions through several initiatives: (1) reusing packaging materials used within processes, (2) preparing the appropriate amount of packaging materials to minimize waste, (3) reducing defective products (plastic waste) by improving yield, (4) reusing scrap generated during manufacturing, (5) reviewing raw material containers, and (6) ensuring thorough sorting to recycle plastic waste.

CHECK & ACT

For industrial waste, we will control waste generation to increase the recycling rate of waste from our operations at home and abroad.

Recycling Resources